STRAINED VISION

Wilson H. Goode

See it On Campus: Level 2

Visitor InfoRennie Hall

Strained Vision is a project that can be viewed through two lenses. The first is an ergonomic one. Following the testing of some early prototype glasses, an opportunity to design a pair of highly adjustable frames came into focus. The adjustablility of the width was the priority. This was achieved with a bow like mechanism that flexes the frame and lenses through cable tension conforming to the wearers face. The second lens is one of sustainable material research. While materials were heavily scrutinized for each element of the glasses, special attention was paid to the lens material.

Mechanical Problem Solving

Key Mechanical Issues

- As the lenses bow inward, so do the end stops of the arm hinges. This means they are no longer parallel.

- Bowing the lenses creates progressively longer arms.

- Due to the cable routing the user has poor mechanical advantage.

Lens Material Research

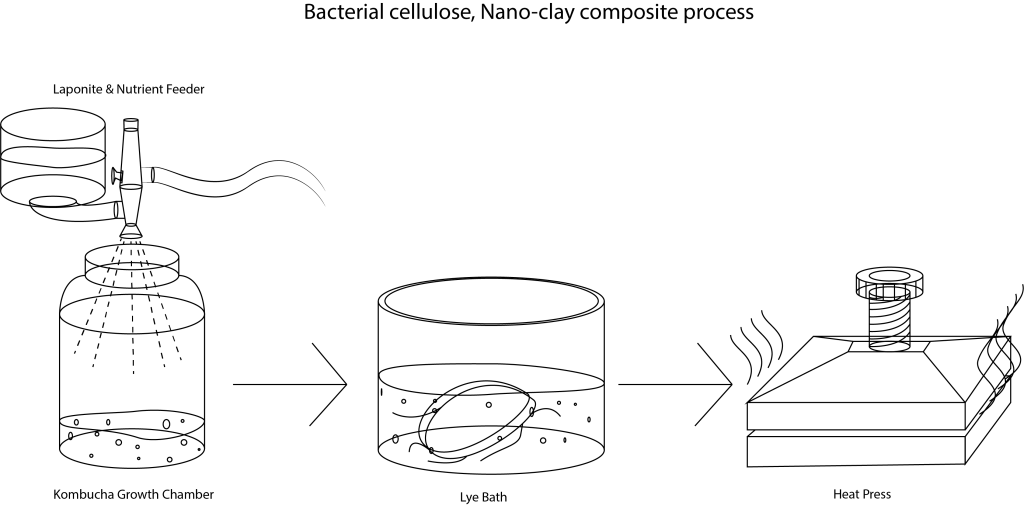

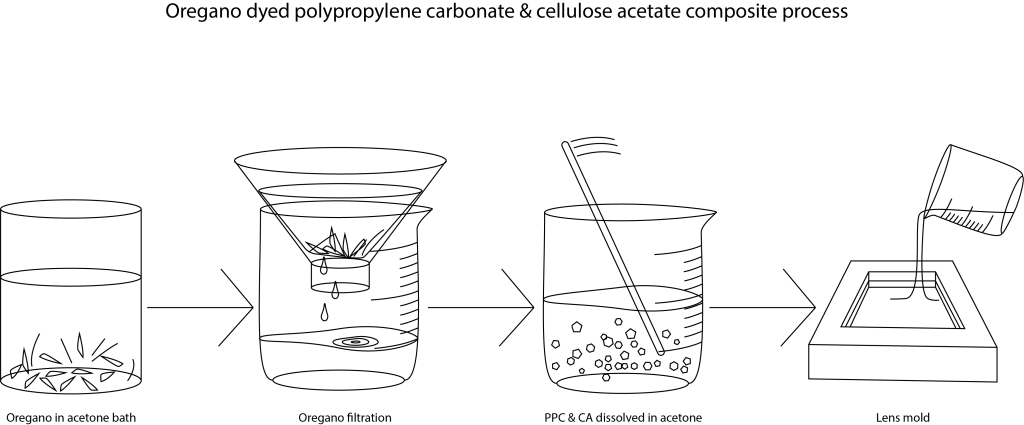

Three potential experimental transparent materials were studied with the hope of replacing industry standard polycarbonate.

- Bacterial cellulose and laponite (nacre like composite)

- Polypropylene carbonate, cellulose acetate, and oregano extract waste (biodegradable plastic)

- PPC injected basswood (transparent wood)

Test Results

While none of these materials were viable lens solutions, their properties are worth exploring further. After these tests, DURABIO a plant based polycarbonate was used as a slightly lest impactful alternative.

Final Prototype

Materials:

Frames: 22g 304 stainless steel

Lens: DURABIO (plant based polycarbonate)

Cable: silk

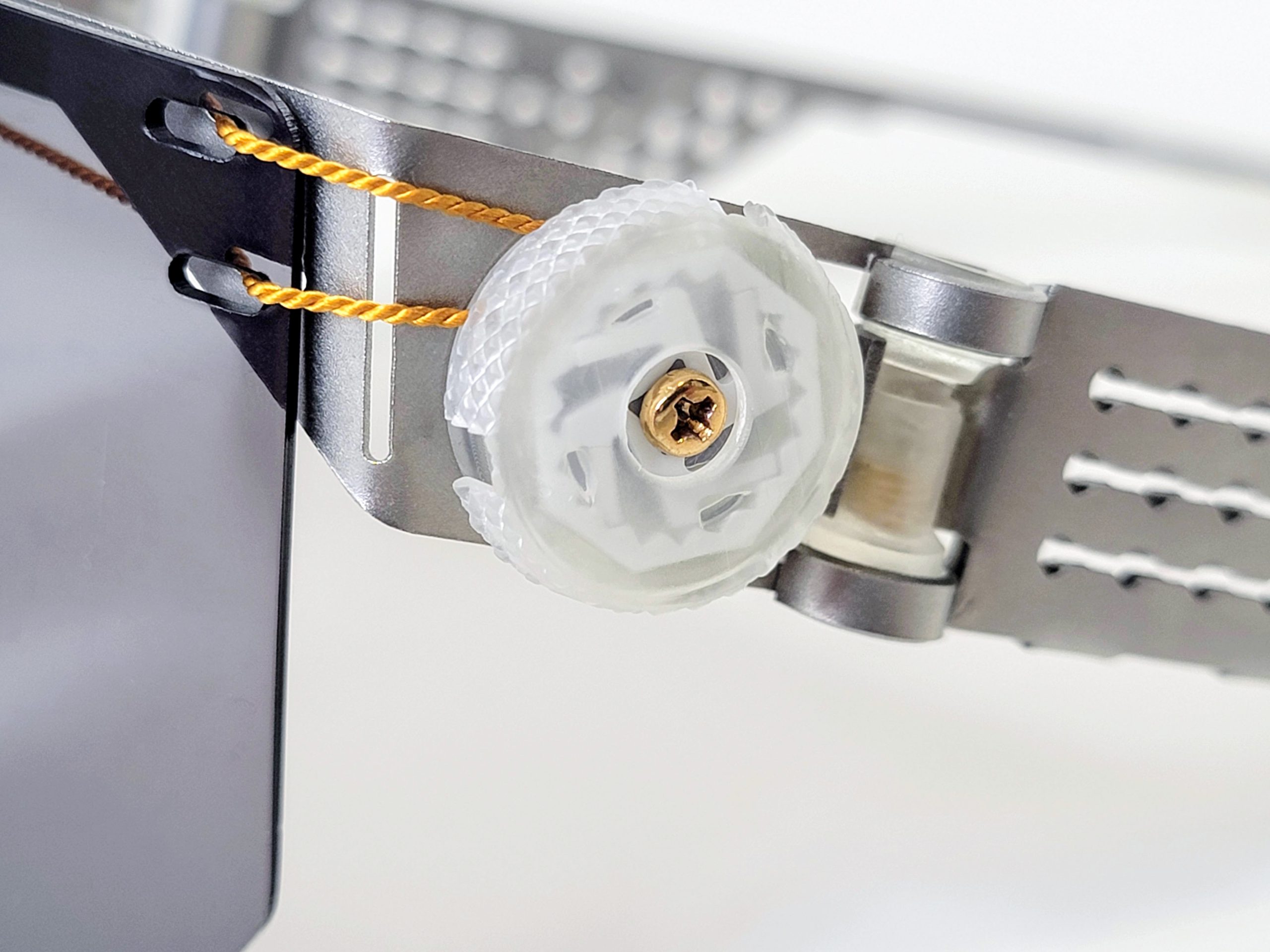

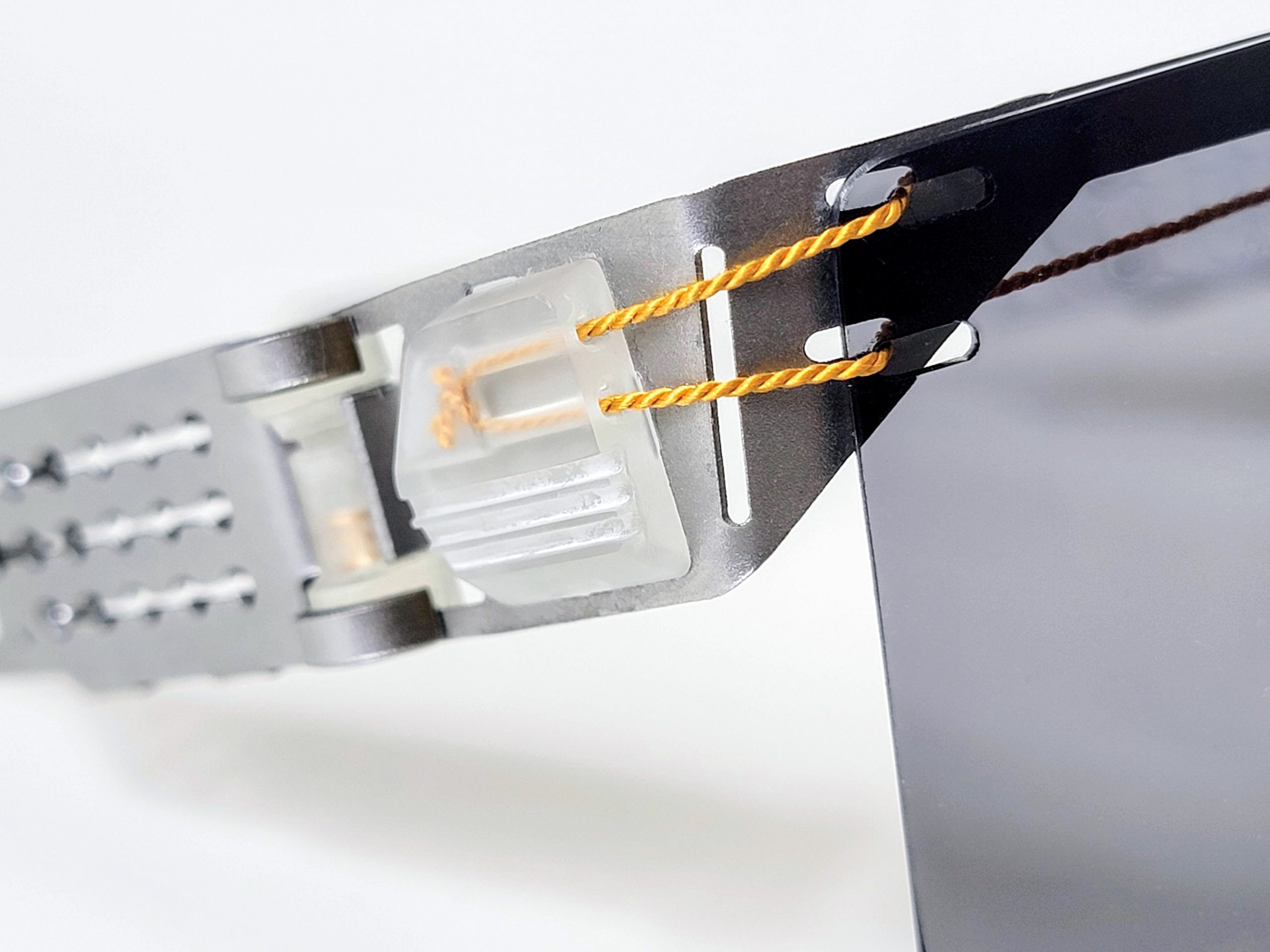

Fittings: photo resin, acrylic, steel

- To improve the mechanical advantage, a bidirectional ratchet system was designed to both tighten and loosen the lenses on the fly.

- To adjust the arm length a simple indexed ball bearing slider was implemented.

- To maintain parallel stopping points the relief cut on the corner of the frame was tuned to allow the outer section to flex outward as the frames bow in.